Groundwater Treatment at AEC1

As the remediation of the landfill is progressing, we are undertaking the final phase of work at AEC1, which was the first area of environmental concern to be successfully remediated. To accomplish this, we are using an advanced technology called Multiphase Extraction (MPE), which is considered the best available technology for this task. This system is highly effective because it removes any substance of concern from both the soil and groundwater at the same time.

The MPE system works by placing special wells into the ground, in this case, 29 wells. These wells act like a powerful vacuum, pulling both liquids and vapours from underground. Once brought to the surface, the materials are separated and treated on-site.

The goundwater is pumped to our water treatment plant for cleaning, while the vapours go through filters with activated carbon - a material that traps any remaining pollutants. T

This process ensures that only clean air is released back into the environment. Once this MPE process is complete in 2027, the ground at AEC1 will be certified as fully remediated.

Data gathered is showing the system is very effective and once completed the results will be used to certify that the area is fully remediated as part of the licence surrender process.

Excavation at AEC1 complete

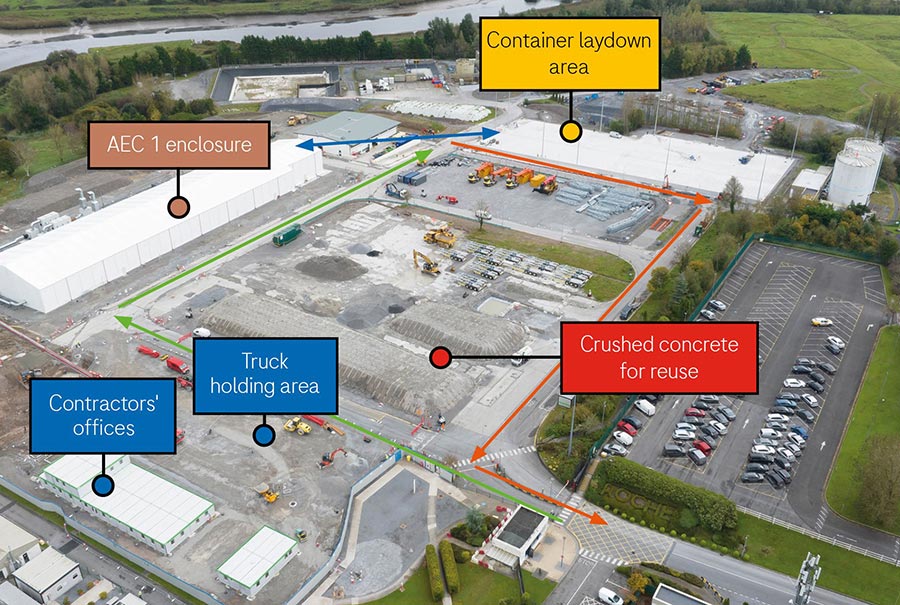

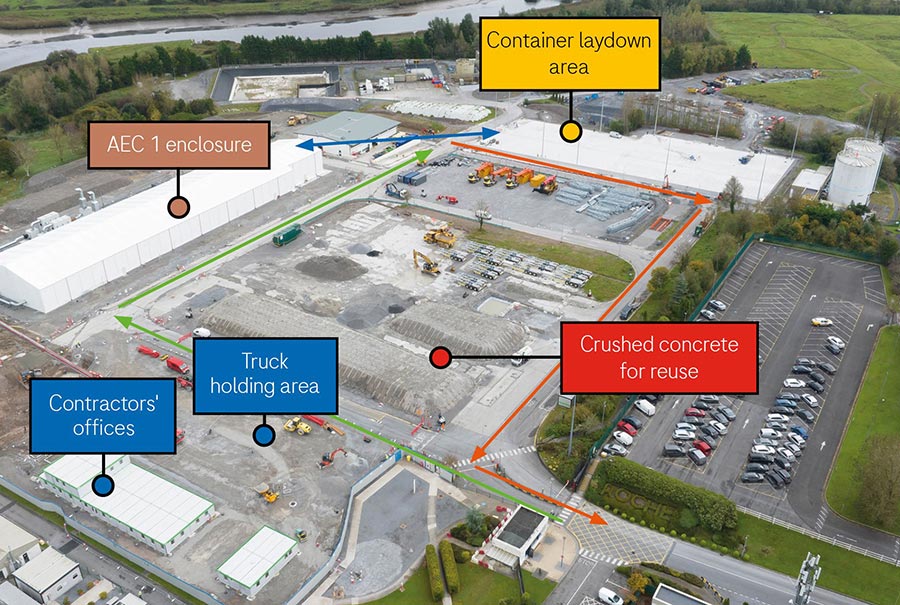

The excavation of contaminated soil in AEC1 commenced in October 2023. Preparatory works to enable this phase to commence started in March 2023. These works, which were planned by the Roche and main contractor (Indaver) teams, included:

- The installation of a container laydown area to store the waste containers.

- A dedicated parking area for HGVs

- The construction of an enclosure, a critical element of the entire remediation project.

Construction of the Enclosure

Minimising the impact on the community is a key consideration in undertaking the remediation works on-site. The construction of temporary negative pressure enclosures is a critical element of the entire remediation project as it provides the engineering solution to contain any odours or emissions that might be generated during the excavation of the contaminated areas of the site being removed as part of the project. Emissions are purified using a charcoal scrubber system.

The enclosure at AEC1 was 110m long x 26m wide and 13m high. It was taken down once the remediation was complete, and is now being used for the remediation of Cells 5, 6 and 7 at the landfill.

The excavation process at AEC1 involved:

-

Empty, closed, containers were transported from the container laydown area to the enclosure entrance. This was done using a machine known as a Movella.

-

The container remained on the Movella and was held in the air lock section of the enclosure until given clearance to enter the excavation section.

-

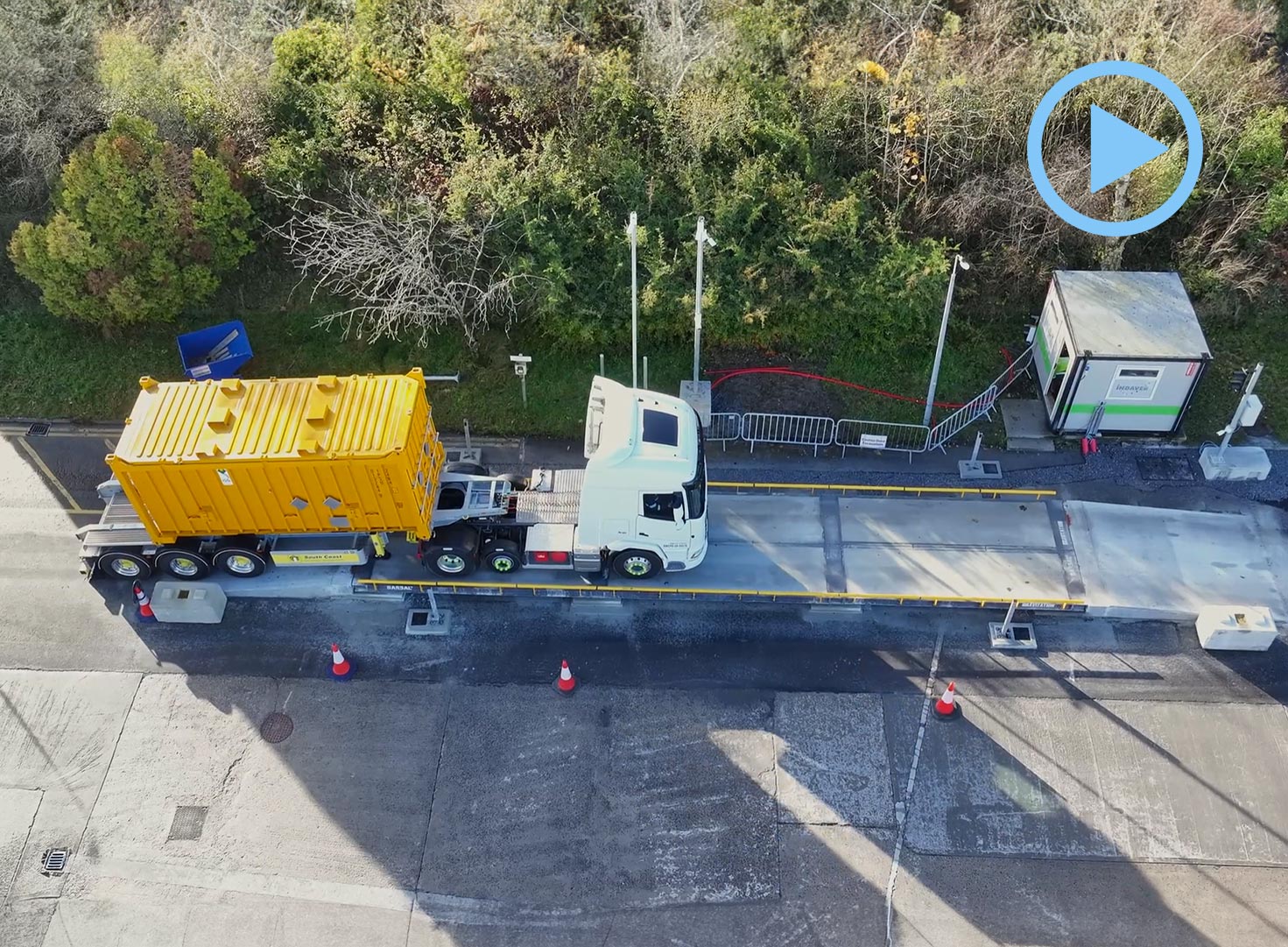

Once the container entered the excavation section, the lid was removed. The container was then placed on a weighing scale, (built into the ground), and was filled whilst on the scale to ensure adherence to the 20tonne weight limit.

-

The contaminated soil was removed by a digger and placed into the container.

-

A funnel was put over the rim of the container to ensure that the container was kept clean during the filling process.

-

Once filled, the container was closed, sealed, and placed back onto the Movella. It then moved into the air lock section where it was washed before being transported back to the container laydown area.

A similar process is being used for the remediation of the landfill.

Key Facts

-

All waste material excavated within the enclosure was placed into specialist sealed containers.

-

Containers were cleaned prior to exit from the enclosure.

-

The wheels of all trucks are washed prior to leaving the site.

-

All entrance and exit points to the enclosure included appropriate containment to mitigate potential dust, odour, and vapour release.

-

Vehicular and personnel decontamination units placed within containment systems mitigated cross contamination.

-

All waste material taken from AEC1 was taken in sealed containers, via the existing road network: Clarehill, Patrick Street, Barrack Street via the R458 and N85 to the M18 (Exit 11), to Shannon Foynes Port.